[technical solution] can 100A current run on PCB? High current path setting skills

[technical solution] can 100A current run on PCB? High current path setting skills

Generally, the design current of PCB will not exceed 10a, even 5A. Especially in household and consumer electronics, the continuous working current on PCB usually does not exceed 2A. But recently, we need to design the power wiring for the company's products, and the continuous current can reach about 80A. Considering the instantaneous current and leaving margin for the whole system, the continuous current of the power wiring should be able to withstand more than 100A.

So the question is, what kind of PCB can withstand the current of 100A?

Method 1: wiring on PCB

To understand the over-current capability of PCB, we first start with PCB structure. Taking double-layer PCB as an example, this kind of circuit board is usually three-layer structure: copper sheet, plate and copper sheet. Copper sheet is the path of current and signal in PCB. According to middle school physics knowledge, we can know that the resistance of an object is related to material, cross-sectional area and length. Because our current is running on the copper sheet, the resistivity is fixed. The cross-sectional area can be regarded as the thickness of copper sheet, which is the thickness of copper in PCB processing options. Usually, the copper thickness is expressed as Oz, the copper thickness of 1 oz is converted to 35 μ m, 2 oz is 70 μ m, and so on. So it is easy to draw a conclusion: in order to pass high current on PCB, the wiring should be short and thick, and the thicker the copper thickness of PCB, the better.

In fact, there is no strict standard for the length of wiring in engineering. In engineering, the current carrying capacity of PCB is usually measured by copper thickness / temperature rise / wire diameter.

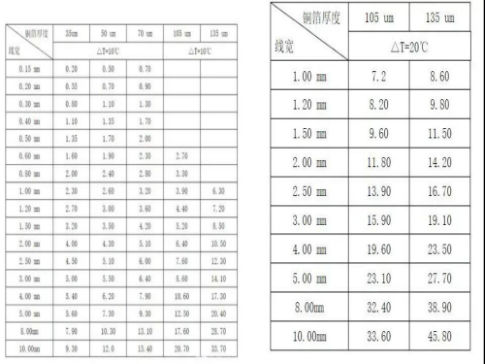

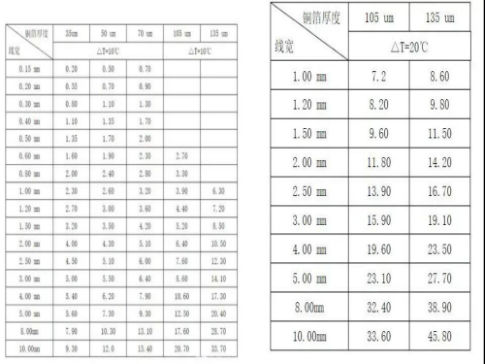

The following two tables can be referred to:

It can be seen from the table that a 100 Mil (2.5 mm) wide wire can pass 4.5 a current for a circuit board with 1 oz copper thickness at 10 ° temperature rise. And with the increase of the width, the current carrying capacity of PCB does not increase in strict accordance with the linear, but the increase rate decreases slowly, which is also consistent with the actual engineering situation. If the temperature rise is increased, the current carrying capacity of the conductor can also be improved.

Through these two tables, we can get PCB wiring experience: increasing copper thickness, widening wire diameter and improving PCB heat dissipation can enhance the current carrying capacity of PCB.

So if I want to run 100A current, I can choose 4 oz copper thickness, wiring width is set to 15mm, double-sided wiring, and add heat dissipation device to reduce PCB temperature rise and improve stability.

Method 2: terminal

In addition to wiring on PCB, wiring can also be done in the way of terminal.

Fix several terminals that can withstand 100A on PCB or product shell, such as surface mount nut, PCB terminal, copper post, etc. Then connect the wire that can withstand 100A to the terminal with copper nose and other terminals. In this way, large current can go through the wire.

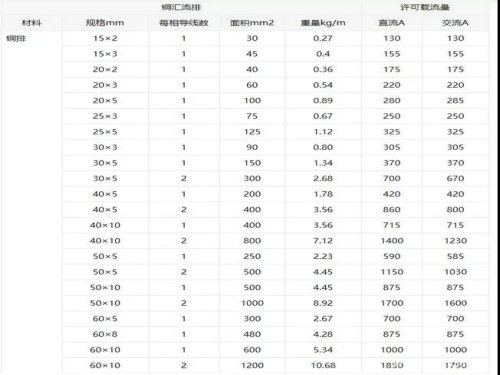

Method 3: custom made copper bar

Even, copper bars can be customized. It is a common practice in industry to use copper bar to run high current, such as transformer, server cabinet, etc.

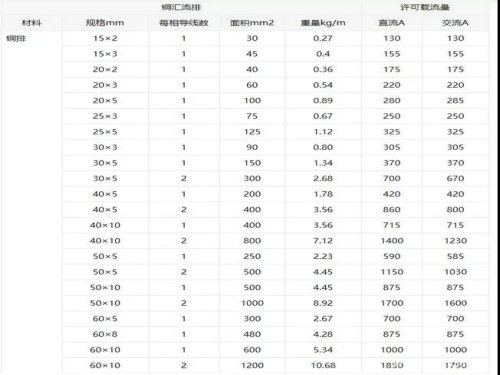

The current carrying capacity table of copper bar is attached

Method 4: special technology

In addition, there are some special PCB process, domestic manufacturers may not be able to find processing. Infineon has a kind of PCB, which adopts 3-layer copper layer design. The top and bottom layers are the signal wiring layer, and the middle layer is the copper layer with the thickness of 1.5mm, which is specially used for power layout. This kind of PCB can easily achieve small volume over-current of more than 100A.

Generally, the design current of PCB will not exceed 10a, even 5A. Especially in household and consumer electronics, the continuous working current on PCB usually does not exceed 2A. But recently, we need to design the power wiring for the company's products, and the continuous current can reach about 80A. Considering the instantaneous current and leaving margin for the whole system, the continuous current of the power wiring should be able to withstand more than 100A.

So the question is, what kind of PCB can withstand the current of 100A?

Method 1: wiring on PCB

To understand the over-current capability of PCB, we first start with PCB structure. Taking double-layer PCB as an example, this kind of circuit board is usually three-layer structure: copper sheet, plate and copper sheet. Copper sheet is the path of current and signal in PCB. According to middle school physics knowledge, we can know that the resistance of an object is related to material, cross-sectional area and length. Because our current is running on the copper sheet, the resistivity is fixed. The cross-sectional area can be regarded as the thickness of copper sheet, which is the thickness of copper in PCB processing options. Usually, the copper thickness is expressed as Oz, the copper thickness of 1 oz is converted to 35 μ m, 2 oz is 70 μ m, and so on. So it is easy to draw a conclusion: in order to pass high current on PCB, the wiring should be short and thick, and the thicker the copper thickness of PCB, the better.

In fact, there is no strict standard for the length of wiring in engineering. In engineering, the current carrying capacity of PCB is usually measured by copper thickness / temperature rise / wire diameter.

The following two tables can be referred to:

It can be seen from the table that a 100 Mil (2.5 mm) wide wire can pass 4.5 a current for a circuit board with 1 oz copper thickness at 10 ° temperature rise. And with the increase of the width, the current carrying capacity of PCB does not increase in strict accordance with the linear, but the increase rate decreases slowly, which is also consistent with the actual engineering situation. If the temperature rise is increased, the current carrying capacity of the conductor can also be improved.

Through these two tables, we can get PCB wiring experience: increasing copper thickness, widening wire diameter and improving PCB heat dissipation can enhance the current carrying capacity of PCB.

So if I want to run 100A current, I can choose 4 oz copper thickness, wiring width is set to 15mm, double-sided wiring, and add heat dissipation device to reduce PCB temperature rise and improve stability.

Method 2: terminal

In addition to wiring on PCB, wiring can also be done in the way of terminal.

Fix several terminals that can withstand 100A on PCB or product shell, such as surface mount nut, PCB terminal, copper post, etc. Then connect the wire that can withstand 100A to the terminal with copper nose and other terminals. In this way, large current can go through the wire.

Method 3: custom made copper bar

Even, copper bars can be customized. It is a common practice in industry to use copper bar to run high current, such as transformer, server cabinet, etc.

The current carrying capacity table of copper bar is attached

Method 4: special technology

In addition, there are some special PCB process, domestic manufacturers may not be able to find processing. Infineon has a kind of PCB, which adopts 3-layer copper layer design. The top and bottom layers are the signal wiring layer, and the middle layer is the copper layer with the thickness of 1.5mm, which is specially used for power layout. This kind of PCB can easily achieve small volume over-current of more than 100A.